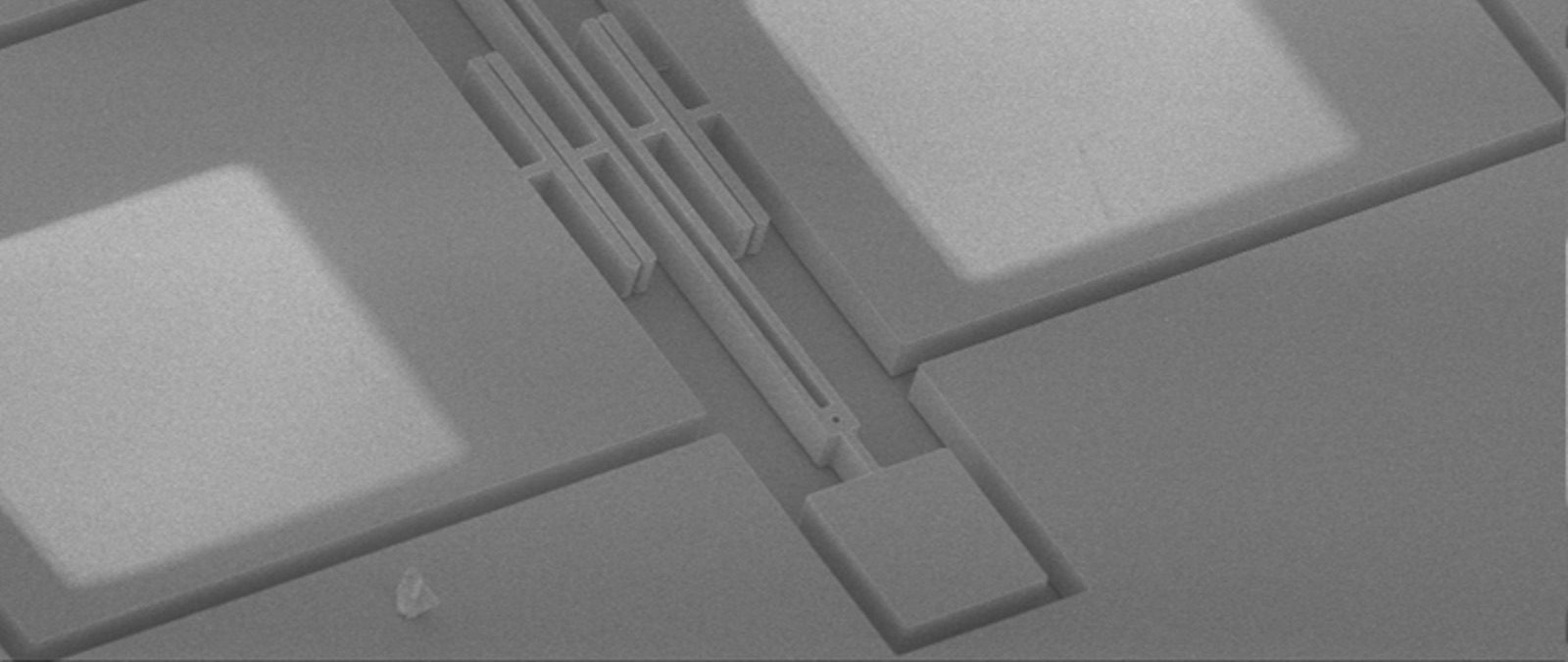

NANOMEMS-X: NANO composites and MEMS based Integrated Circuits Sensor Systems

The project involves the construction of new Strain sensors with high sensitivity and a wider measurement range, which allow to realize innovative applications, able to give a competitive advantage both to manufacturers of mechatronic components and to machine manufacturers. These sensors will be realized using two different technologies: one belongs to the MEMS type and the other is based on elastic nanocomposites, to have greater applications. The innovation and the functional principles of the components, allow on one hand to create sensors with high sensitivity and on the other to obtain products covered by worldwide patents (therefore not producible for traditional technologies). The project involves the application of Strain Sensors on rigid supports for the realization of sensors of stress, deformation, force, torque and pressure on mechanical devices, in positions where traditional technologies would be null. These devices will be also used to create non-invasive pressure sensors, meaning they don’t require a direct contact with the fluid, giving space to a new class of smart components in the hydraulic system, that finds its excellence in Emilia Romagna region.

Strain elastic sensors based on conductive nanocomposite materials (CTPE), obtained by micro-extrusion, will be used to measure fluid pressure in hoses, for the production of tactile systems to be integrated directly on operator commands or to monitor the status of tires. These devices consist of very low-cost material (4 cents / gr.) and allow to build external systems that will be applied on previous existing systems. All the sensors will be realized with a digital electronic system, able to supply both information in analog format and communication networks used in the machines.